Blast Resistant Door

An explosion is a sudden release of gas at high pressure in the environment. Sudden, because the release must be sufficiently rapid for the energy contained in the gas dissipated via a shock wave.

Blast protection is one of today's biggest challenges. A Petro-chemical blast may be regarded as different to that of a terrorist blast attack but fundamentally, blast doors and windows will have to perform the same task - protecting people, places and possessions.

Blast Protection

- • DIN EN 13123 & 13124 certified

- • ASCE requirements compliant

- • Design calculation certified

- • Third party approved

Fire Rating

- • Up to 3 hours fire rated

- • UL10C certified

- • Rockwool infill insulation

- • Welded steel framework

Finishes

- • Polyester powder coating

- • Standard RAL colors

- • Factory applied epoxy prime base coat

- • Custom color options

General Information

Fitzpatrick blast resistant doors are manufactured to meet the international requirements of blast pressure based on design calculations and certified by an approved third party consultancy offices in accordance with industry standards.

Fitzpatrick's blast doors are manufactured from steel, with an inner welded framework connected to front and rear doors skins with multiple welds. The voids between reinforcing members are entirely filled with Rockwool infill.

All construction details, reinforcement, and frame anchoring, depend solely on the calculation design of the specified blast pressure.

Standards and Requirements

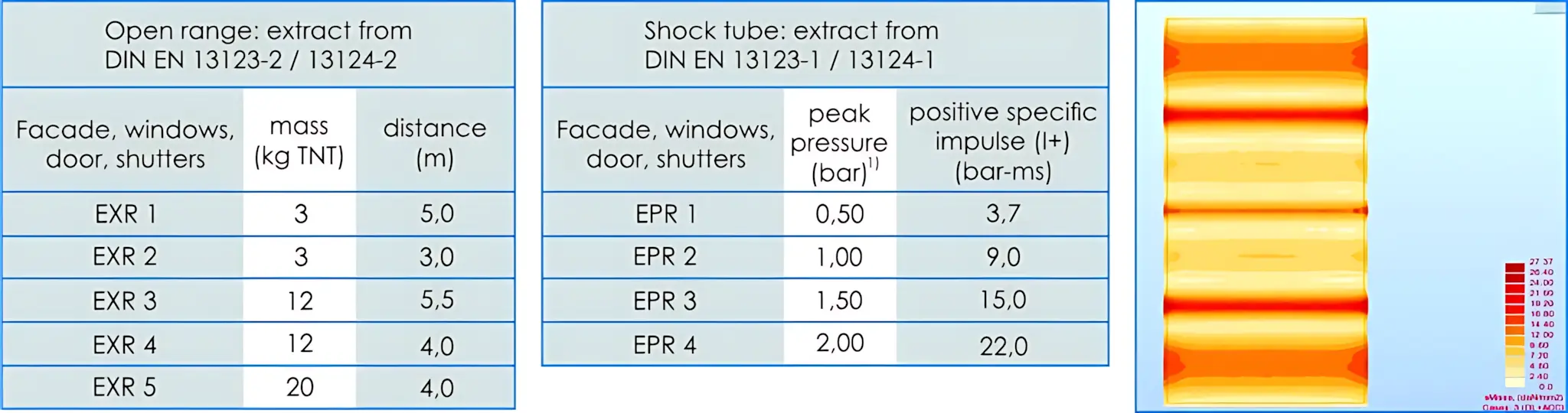

Open Range: DIN EN 13123-2 & 13124-2

Shock Tube: DIN EN 13123-1 & 13124-1

Industry Requirements: Petro-chemical industry according to ASCE